Laboratory

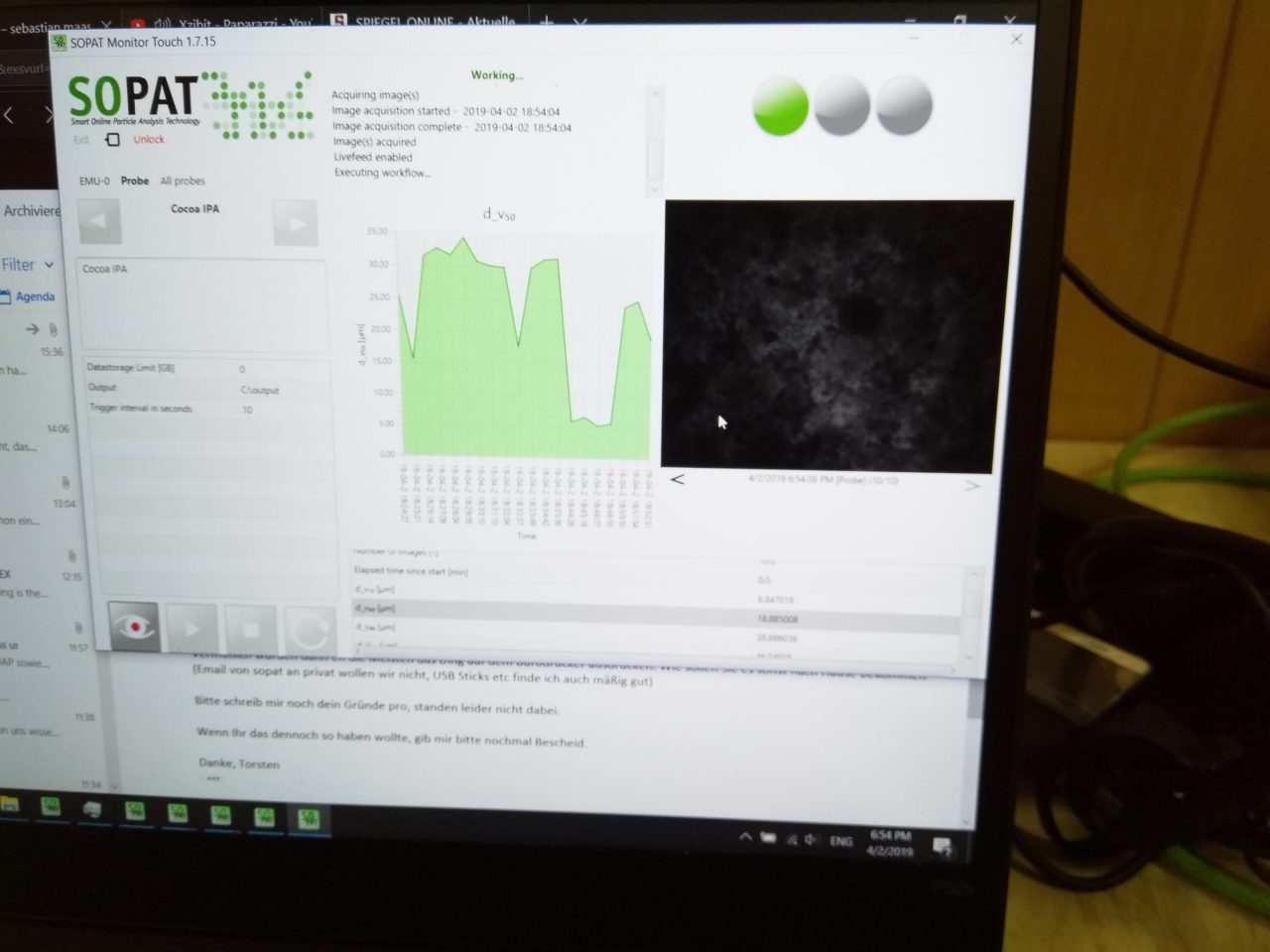

SOPAT

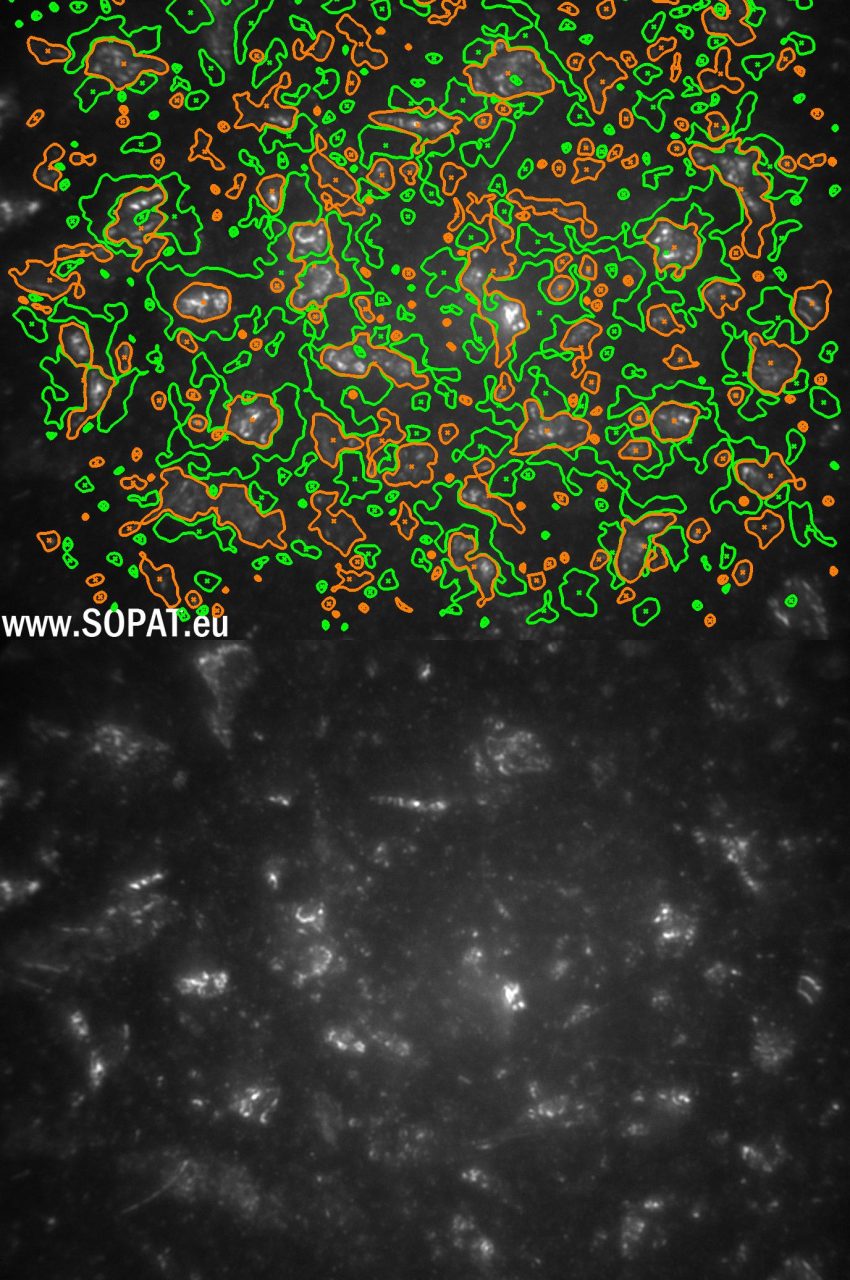

SOPAT is a leading provider of innovative particle measurement solutions, delivering real-time, in-situ analysis through advanced photo-optical technology. Our systems allow you to visualize, measure, and analyze particle size and shape directly within your process, eliminating the need for manual sampling or laboratory delays.

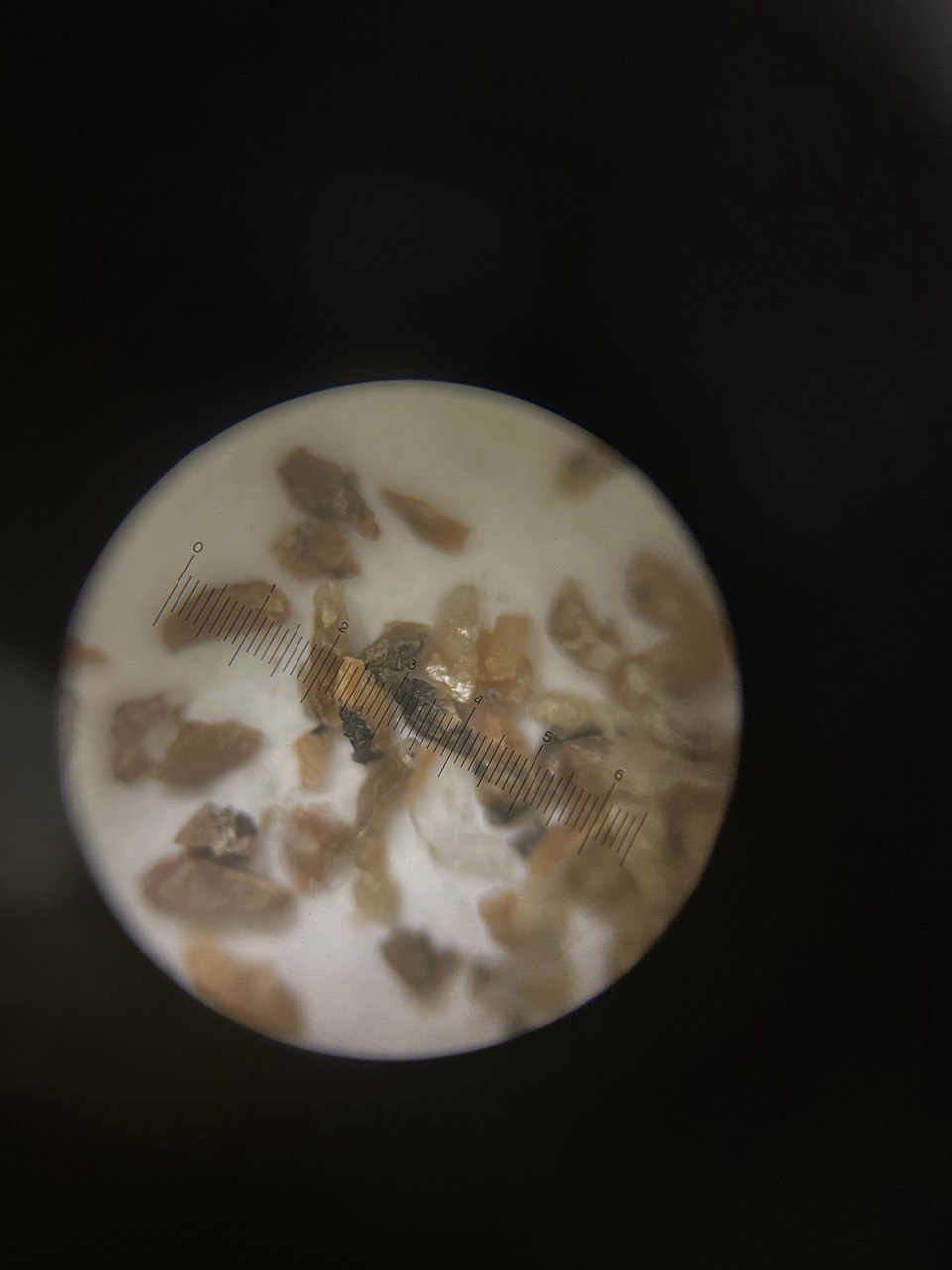

In the mining and mineral processing industry, particle size and distribution are critical parameters for efficient separation, grinding, and flotation processes. SOPAT provides real-time, in-situ particle analysis, enabling operators to monitor and control these parameters directly in the slurry — without delays or manual sampling.

By integrating SOPAT systems into pipelines, tanks, or reactors, companies gain continuous insight into particle behavior, helping to:

Optimize grinding efficiency

Improve flotation performance

Reduce reagent consumption

Enhance overall recovery rates

With SOPAT, you gain faster response times, improved process control, and better product consistency — all while minimizing downtime and operating costs.

A Smart Solution for Process Automation

Automating Mineral Processing with SOPAT

We utilize SOPAT’s real-time particle analysis technology to automate and optimize key processes in the mining and mineral processing industry. By integrating SOPAT systems directly into our processing lines, we gain continuous, in-situ monitoring of particle size and distribution — without the need for manual sampling or lab analysis.

This enables:

Automated process adjustments based on live data

Improved grinding and flotation efficiency

Consistent product quality and higher recovery rates

Reduced downtime and operating costs

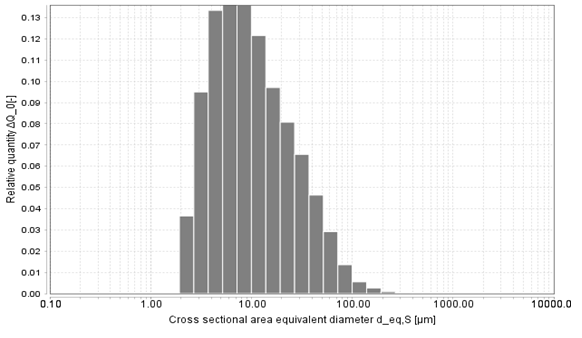

Our laboratory operates in accordance with ISO 13322-1, 13322-2 ensuring that our image-based particle size measurements meet the highest international standards for reliability and accuracy.

SOPAT empowers us to make data-driven decisions in real time — enhancing performance, quality, and control.